PCB Design & Manufacturing: Printed Circuit Boards for Your Needs

- Home

- PCB Design & Manufacturing – NOFFZ Technologies

Custom-specific and individual

PCB Design & Manufacturing - NOFFZ Technologies

Tailored solutions for your needs

We provide consulting, development, design, and manufacturing of custom hardware solutions precisely tailored to your projects – from custom printed circuit boards (PCBs) to signal conditioning and measurement devices.

What sets us apart

Our services at a glance

- Expert consultation

- THT, SMD, and BGA (Ball Grid Array) assembly

- Wave soldering | Reflow soldering | Hand soldering

- Small and medium series production

- Development of loadboards (up to 25 layers)

- Development of probecards and interface boards (optimal complement for COTS tester platforms)

Expert PCB manufacturing and assembly for fast and precise results

We offer professional PCB services for prototypes to medium series. As your central point of contact for high-quality printed circuit boards, we support you with our qualified experts from the initial idea to the production-ready PCB. With us, you’ll find tailored solutions for your projects.

Thanks to the optimization of our manufacturing processes, we have established a dedicated area for PCB production, managed by experts from our team. Our engineers and technicians work closely with you to ensure the highest quality and the fastest possible lead times.

Our PCB services include SMT, BGA, THT, and mixed assembly, rigid-flex PCB assembly, as well as electromechanical assembly, box build assembly, product assembly, and cable assemblies. All work is performed according to the IPC 610 Class 2 and 3 quality standards to meet your requirements for quality and precision.

Additionally, we offer comprehensive solutions in embedded design. Using state-of-the-art tools, we develop custom circuits and PCB layouts that are perfectly tailored to your requirements. Our expertise also includes embedded software development, allowing us to successfully implement microprocessor solutions and FPGA applications. Further applications can be found in high-speed interfaces as well as custom card solutions for signal conditioning and switching.

Through close partnerships with leading chip manufacturers, we have early access to roadmaps and new technologies, ensuring that we are optimally prepared for future applications.

Modern manufacturing technology for the highest quality

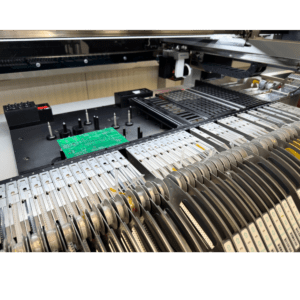

For precise and reliable manufacturing, we rely on state-of-the-art equipment. Our facility is equipped with advanced machines that ensure efficient and high-quality production:

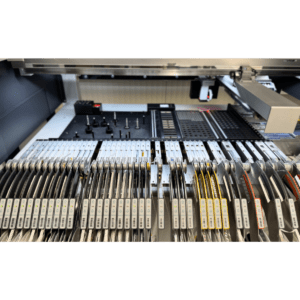

- Pick-and-place machine: Automatic and precise placement of electronic components for fast and error-free production.

- Vapor phase soldering system: Gentle and uniform soldering for the highest connection quality, ideal for complex assemblies.

- Reflow oven: Reliable soldering with optimal temperature profiles for secure component connections.

- Optical inspection system: Automated quality control to detect the smallest defects and ensure the highest standards.

- Repair station: Professional rework and repair of assemblies for maximum durability of your products.

- Solder paste printer: Precise application of solder paste for flawless component placement and soldering quality.

Our equipment enables efficient production, the highest precision, and comprehensive quality control.

Our PCB manufacturing expertise

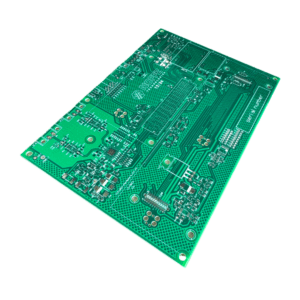

Printed circuit boards (PCBs)

Single-sided and double-sided PCBs, multilayer boards with multiple layers, as well as flexible and semi-flexible boards, are precisely manufactured. We produce prototypes, series, and custom designs according to individual requirements.

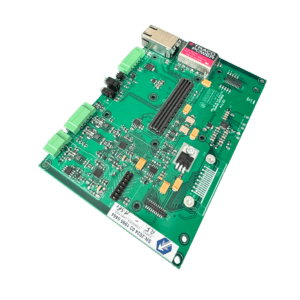

PCB assembly

THT, SMD, and BGA assembly, LED and mixed assembly, as well as vapor phase, reflow, and hand soldering are used. DIP components and SMD parts are efficiently and reliably assembled.

Prototype manufacturing

From circuit design and layout to PCB manufacturing with trace patterns, assembly (THT, SMD, mixed technology), and quality and electrical functionality testing – everything is implemented precisely and reliably.

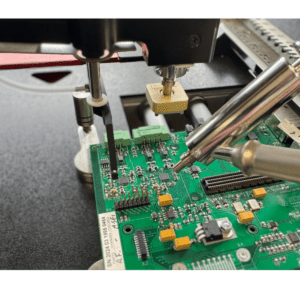

Repair / Rework

The replacement of THT components, SMD, and BGA parts is carried out precisely and professionally. Additionally, we offer cleaning, repair, and maintenance services, as well as fast and reliable procurement of electronic spare parts.

Professional PCB design for efficient results

PCB development

Our experts support you from the initial concept idea to the market-ready PCB. Thanks to state-of-the-art CAD software, we create custom solutions and detailed 3D models, precisely according to your specifications. Whether hardware and software development or PCB layout – we accompany you through every development phase with our expertise and cutting-edge technology.

Software development

We develop customized operating software for electronic assemblies and devices as needed. The focus is on software and test programs for embedded systems as well as custom applications. In PCB development, practical programming with short development times ensures efficient and successful implementation of your software projects.

Hardware development

We take care of the entire hardware development process – from creating circuit diagrams to selecting the optimal PCB materials and suitable components. We focus on EMC and safety requirements, as well as manufacturability, which significantly reduces testing efforts. We also professionally handle the development of enclosures and mechanical components.

PCB layout according to customer specifications

A precise layout and thoughtful design are crucial for the flawless functionality of EMS assemblies. The layer structure, thermal management, signal routing, and component placement are developed exactly according to your requirements and checked for technical feasibility. The result: A manufacturable PCB design that is optimally tailored to your specific needs.

IN ACTION

First steps with the Base Station Emulator

Practical implementation of typical test cases

The Base Station Emulator was developed for signaling tests in validation and production. The video series demonstrates typical scenarios: 1. Establishing a cellular connection, 2. Data transmission in 5G network, 3. Calls over VoIP, 4. Hand-over between mobile cells.

DO YOU HAVE ANY QUESTIONS?

Speak with our experts directly!

Let us know the details of your project. We’re curious about your ideas, products, and requirements and would be glad to advise you specifically about your requests.

Together we’ll make your project a success!

Let’s set up a meeting.