Industrial Test Automation

- Home

- Industrial Test Automation

Highest quality and reliability

Industrial Test Automation

Innovative automation solutions

Automation plays a crucial role in today’s industry. It aims to optimize and simplify processes by minimizing human interventions and instead employing machines and systems to accomplish tasks. We offer the opportunity to automate both manual handling of test systems and to develop fully automated rotary indexing systems, relying on customized solutions tailored to meet individual requirements.

More than just automated test sequences

Our wide range of industrial (test) automation solutions offers individual paths to optimize your manufacturing processes. From expanding existing test systems to implementing complete industrial automation lines to developing highly complex systems in close collaboration with our partners – we support you with our NOFFZ experts. For various requirements, we have developed a modular system that reflects the different levels of automation and is flexible and adaptable.

Automation solutions tailored to your requirements

An overview of our modules

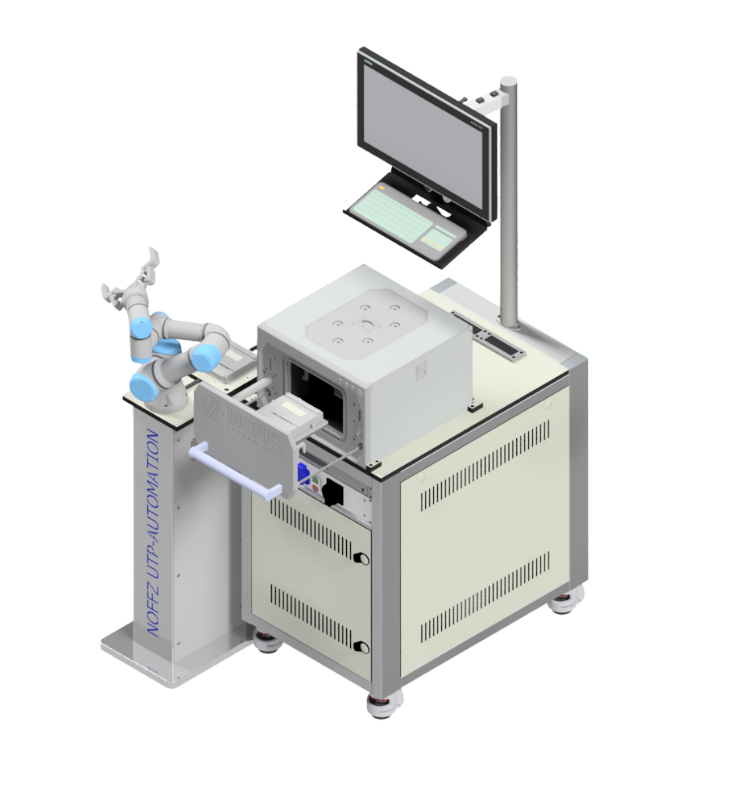

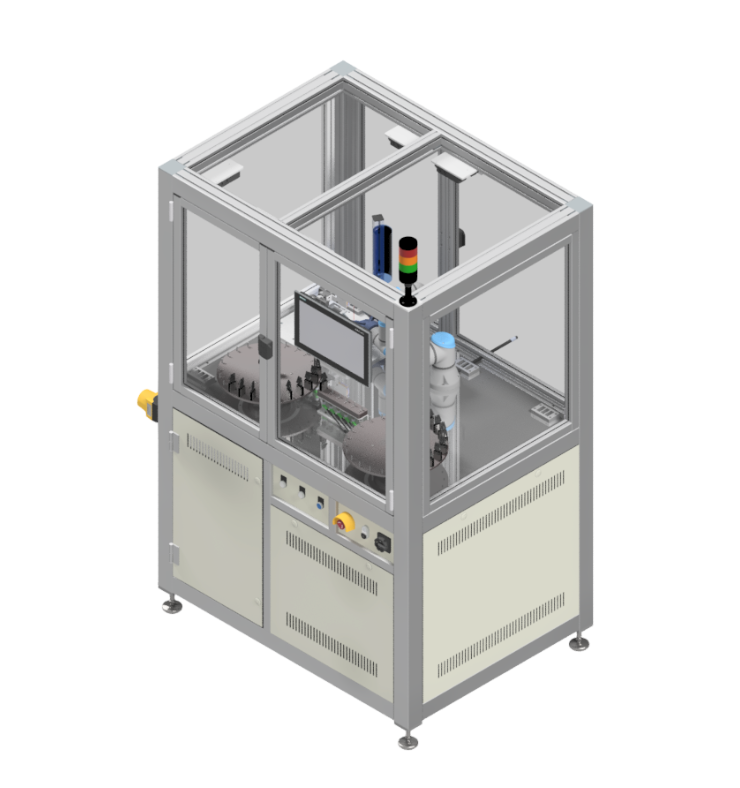

Module 1: Basic Automation

Our industrial (test) automation solution offers an innovative expansion possibility for existing test systems. With the Basic module, we enable automation by integrating a portal, stage, or robot. This approach optimizes your existing workflows by reducing manual processes and increasing efficiency. By seamlessly integrating our automation technologies into your existing infrastructure, you maximize your investment and open up new possibilities for improved performance.

Optimization of existing test systems through automation extensions

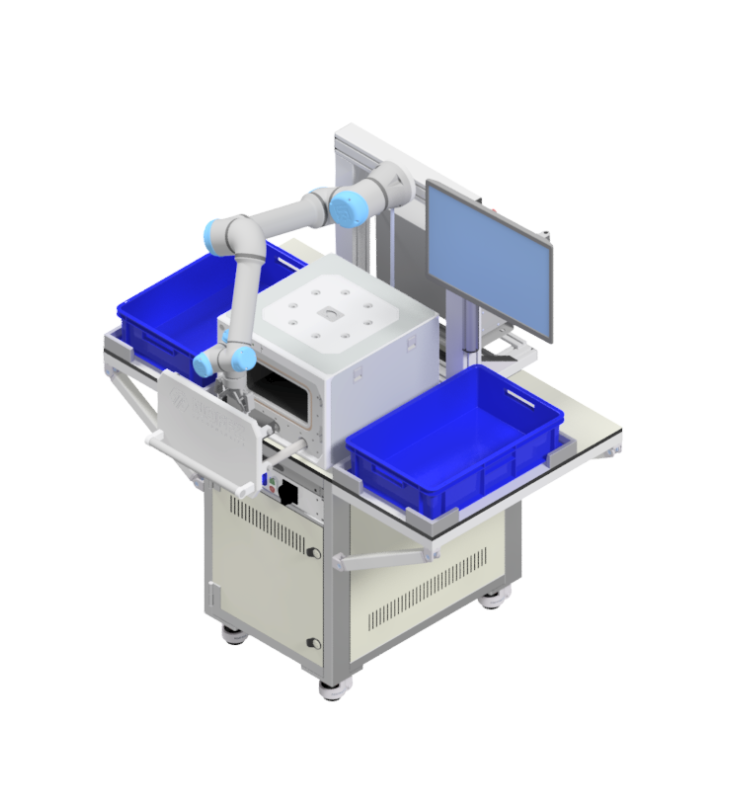

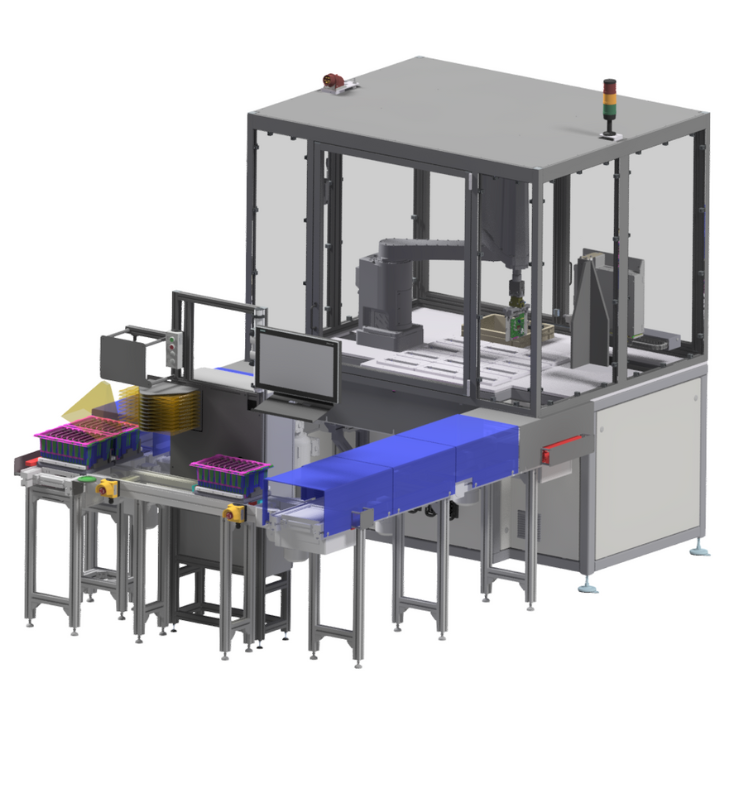

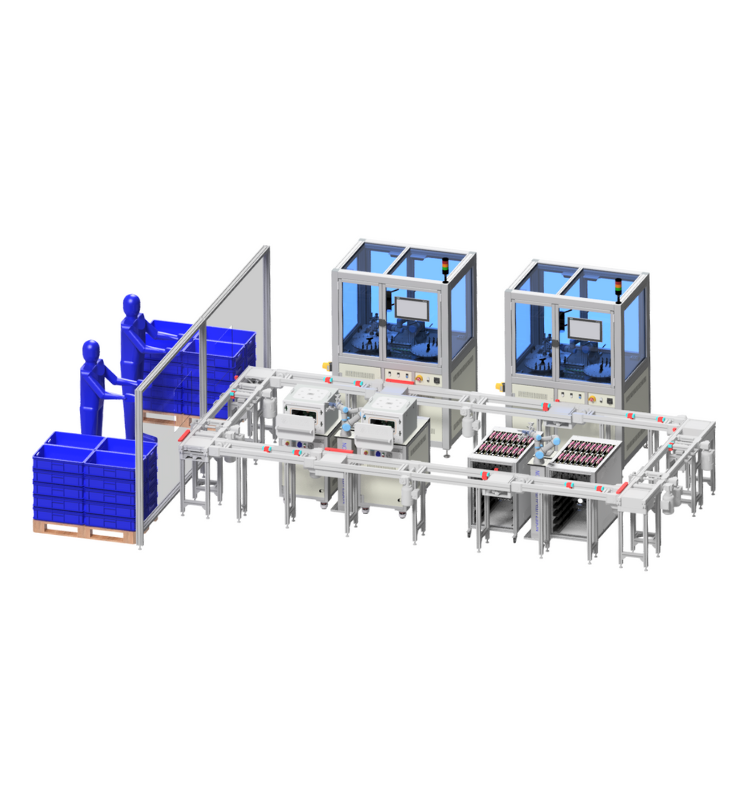

Module 2: Advanced Automation

With our Advanced Automation solution, we offer full automation of your manufacturing processes. Our rotary indexing machines and manufacturing plants enable efficient and reliable production by ensuring a seamless sequence of work steps. From material supply to final assembly, these systems enable smooth operation and maximize production capacity. With this module, you are ready to take your manufacturing to a new level of efficiency and performance.

Full automation with a rotary indexing/manufacturing plant

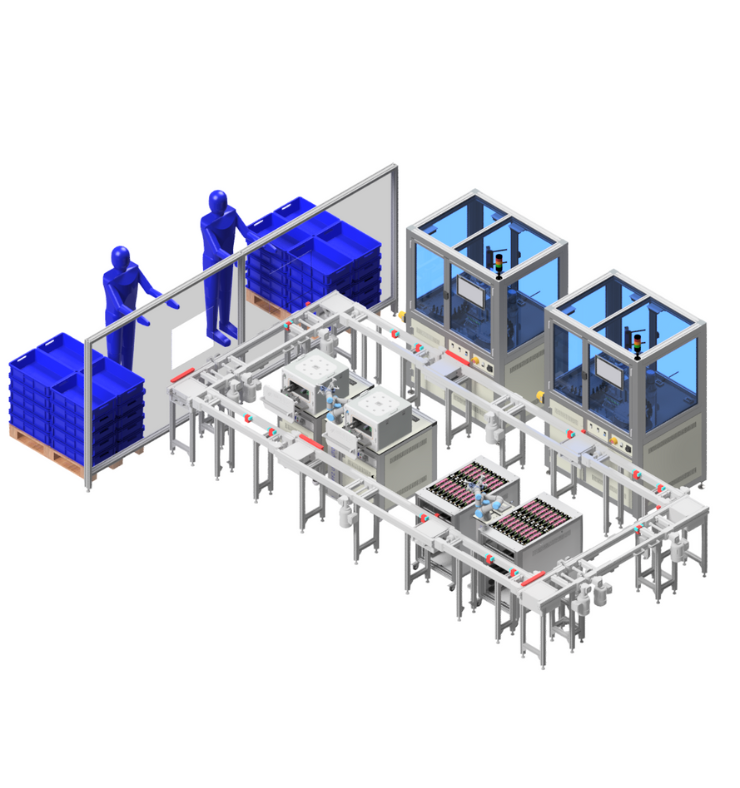

Module 3: Professional Automation

Our Professional Automation offers highly specialized solutions for demanding requirements. We work closely with our partners to develop tailored and highly complex automation systems. These solutions are designed to tackle even the most demanding challenges and provide the highest level of precision, efficiency, and reliability. Through our close collaboration with leading experts in this field, we can ensure that your individual requirements are fully met.

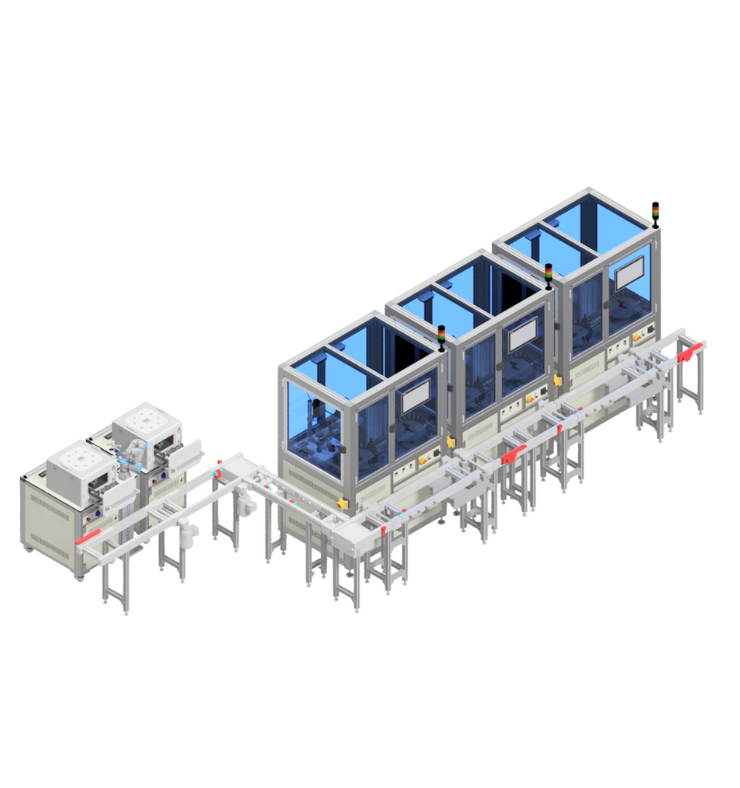

Inline test systems/complex automation systems also in collaboration with our partners

The processes we cover

Integrated Processes

Our system supports a range of test and manufacturing processes, ensuring efficient and reliable operations:

Test Processes:

- ICT (In-Circuit Test) Flashing

- Functional End-of-Line (EOL) Test

- Leakage Test

- Pin Check

- Optical Inspection

Common Supporting Processes:

- Label Printing Application

- Laser Engraving

- Label Verification

- Pass/Fail Separation

- Device Under Test (DUT) Handling Packaging

Optional Processes:

- Resistive Welding

- Laser Welding

- Additional Custom Processes

Features

Key Features

Our automation systems offer several advanced features to optimize your production line:

- Supports one or more DUTs/panels per nest

- Auto lock/unlock of DUT for streamlined operation

- DUT placement control for precision testing

- Automatic contacting of DUT for seamless connection

- Traceability management of DUTs in the machine

- Fail DUT handling to manage defective units efficiently

- Status monitoring for real-time operational insight

- Service doors for easy access during maintenance

- Preventive maintenance to reduce downtime

- Supports various production modes for flexibility

- Multiple maintenance modes to suit different needs

- ERP integration for seamless data exchange with company systems

Processes

Integrated Processes

- Effizienz: Automatisierte Tests können schneller durchgeführt werden als manuelle Tests, da sie in der Lage sind, eine große Anzahl von Testfällen in kurzer Zeit auszuführen. Dies führt zu einer beschleunigten Testdurchführung und verkürzten Entwicklungszyklen.

- Konsistenz: Automatisierte Tests führen zu einer höheren Konsistenz und Genauigkeit bei der Durchführung von Testfällen, da sie frei von menschlichen Fehlern sind. Dadurch wird die Zuverlässigkeit der Testergebnisse verbessert.

- Skalierbarkeit: Automatisierte Tests können leicht skaliert werden, um den Anforderungen von Projekten mit unterschiedlichen Größen und Komplexitäten gerecht zu werden. Sie können problemlos auf mehreren Plattformen und Umgebungen eingesetzt werden.

- Wiederholbarkeit: Durch die Automatisierung von Tests können diese jederzeit wiederholt und beliebig oft ausgeführt werden, ohne dass zusätzliche Ressourcen erforderlich sind. Dies erleichtert die kontinuierliche Integration und das Testen in DevOps- und Agile-Umgebungen.

- Kostenersparnis: Obwohl der initiale Aufwand für die Einrichtung automatisierter Tests höher sein kann, führen sie langfristig zu erheblichen Kosteneinsparungen. Durch die Reduzierung des manuellen Testaufwands können Unternehmen Zeit und Ressourcen sparen.

IN ACTION

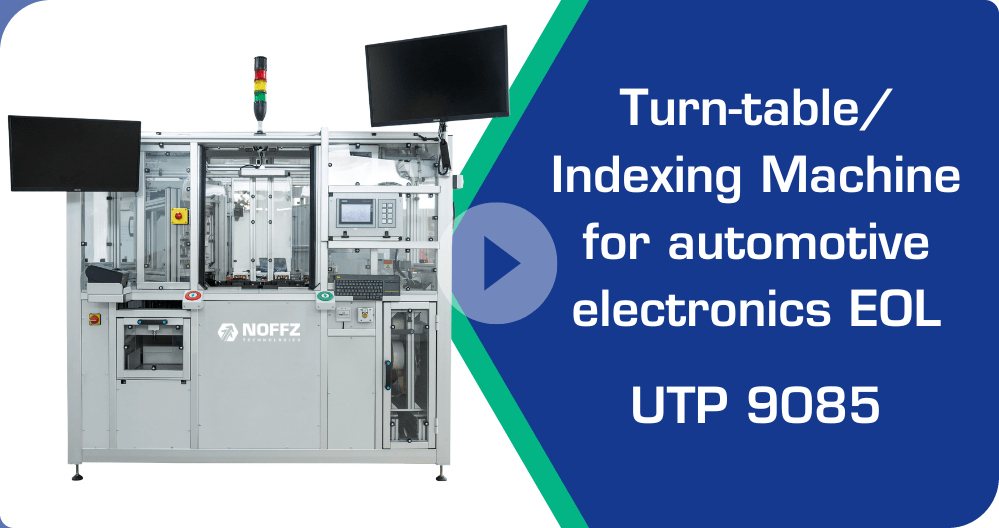

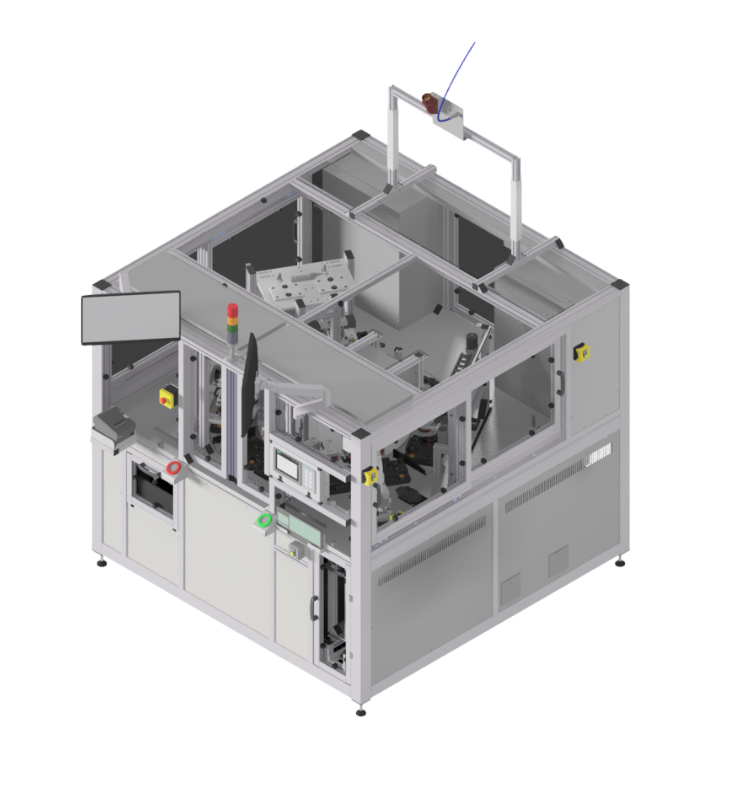

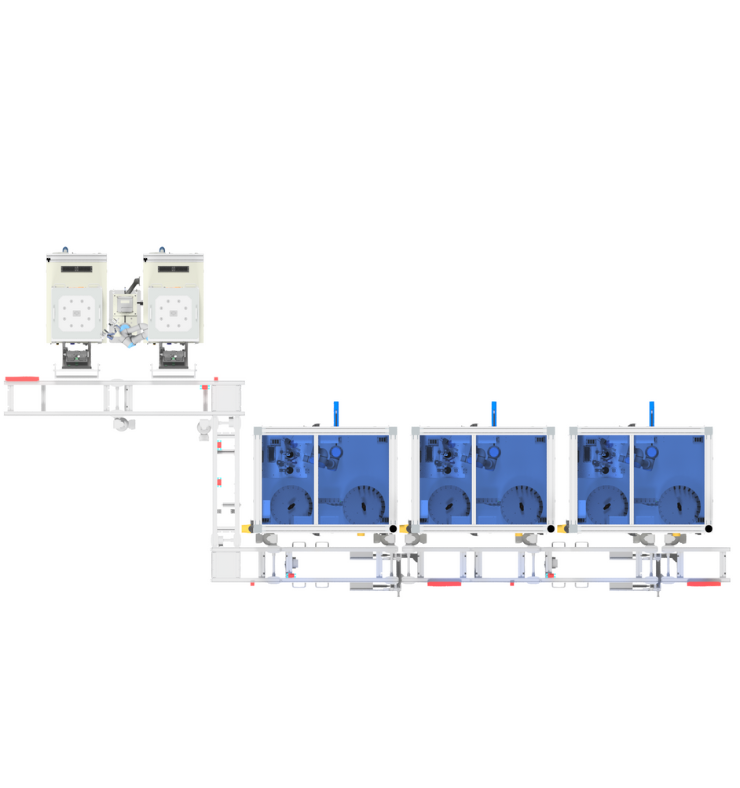

NOFFZ UTP 9085

Rotary table/indexing machine for EOL tests in automotive electronics

Introducing our latest automation solution: the UTP 9085 rotary and indexing machine. This state-of-the-art technology offers a comprehensive range of functions: rotary table and robot integration, multi-stage end-of-line inspection with double unit under test (DUT), optical pin inspection, label printing and application.

DO YOU HAVE ANY QUESTIONS?

Speak with our experts directly!

Let us know the details of your project. We’re curious about your ideas, products, and requirements and would be glad to advise you specifically about your requests.

Together we’ll make your project a success!

Let’s set up a meeting.

Marc Schmidt

Customer Solution Center / Test Automation Solutions

Automotive devices must be reliable.

Combine all products and

measuring instruments in just one rack for validation.

Test devices with high channel counts in parallel.

Modify satellite trajectories. Simulate environments.

Generate a variety of realistic multiband GNSS signals. Define your parameters individually and test them with high precision. Directly in the lab and in real time.

Efficiently test wireless communication devices with a system designed for high-volume parallel testing. It integrates multiple wireless standards into one platform, allowing you to use up to 64 ports simultaneously.

Larger displays and increasing connectivity.

Improved technologies are setting a rapid pace.

These innovations require intelligent test systems.

We create your individual solution with high precision.