The drive technology of the future is here – fuel cells

Probably the most decisive argument for fuel cell drives and thus for sustainable climate protection is obvious. The vehicles of tomorrow will only emit clean water vapor instead of CO2.

To significantly accelerate the series production of reliable fuel cell systems and thus accelerate the energy and mobility transformation.

The use of our completely new state-of-the-art automation and test solutions can be a significant turning point for the industrial production of fuel cells!

Drive technology of the future

Our services for your production

People who want to operate in this trend-setting key market should optimize their production process and focus on the functionality, quality, and reliability of the new systems.

With our high-performance assembly and test solutions, we support you throughout your entire product development cycle for fuel cell systems and components. We also ensure the required error-free top quality.

From validation tests in preliminary and concept development to series production, our system solutions are scalable according to your needs. They are also Industry 4.0 compliant and thus fully automated, featuring product flexibility and consistent data.

1. Assembly of the cells, 2. Assembly of the stack, 3. Compression of the stack, 4. System integration and assembly of the system periphery,

5. Activation of the system and end-of-line test

Change through new technologies

Assembly & fuel cell test solutions for reliable fuel cell systems

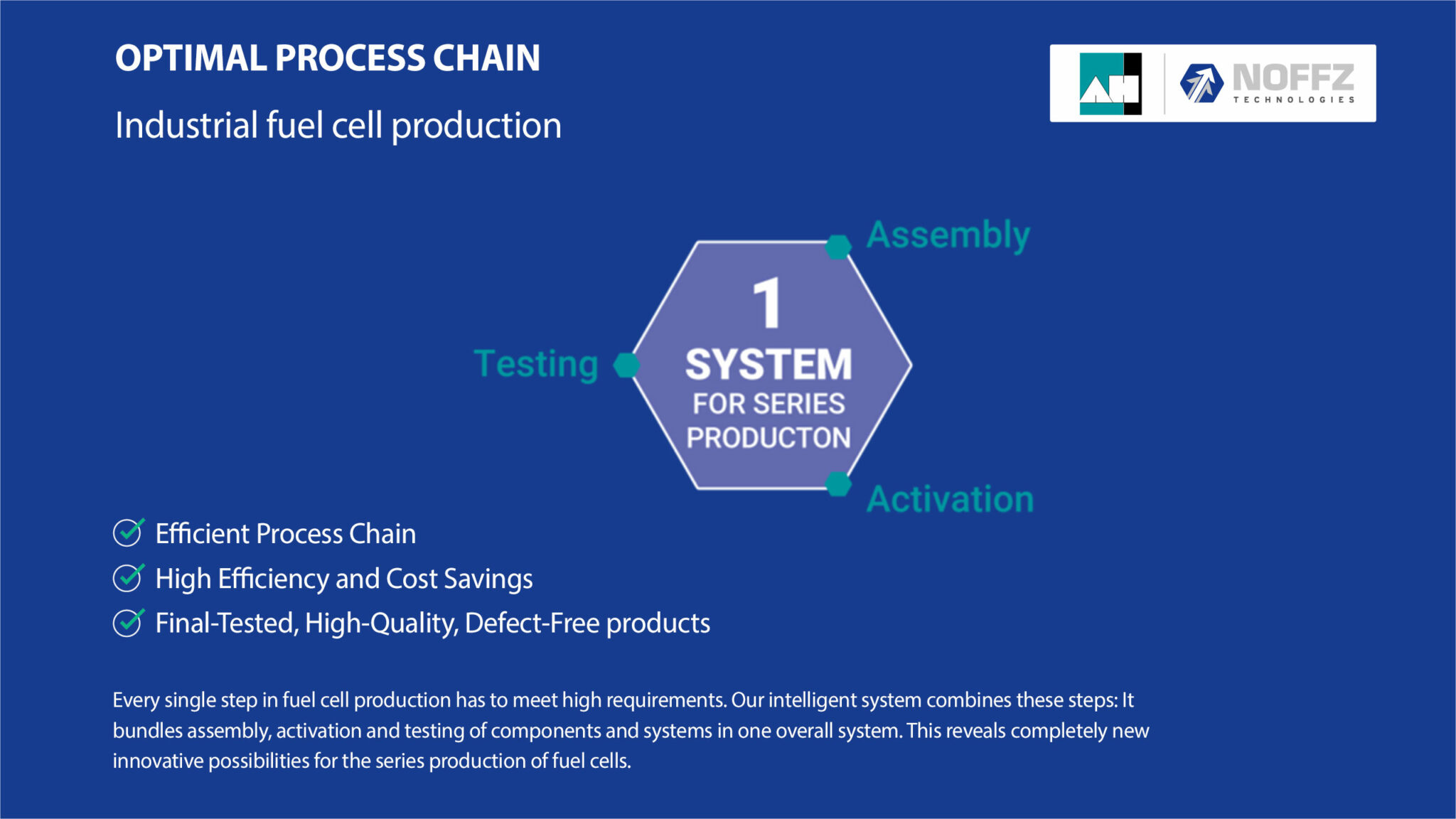

With our combined experience in automation and testing technology, Albert & Hummel and NOFFZ have set a new milestone for series production of fuel cell systems:

In just one production plant, complex manufacturing steps are combined that previously only took place in individual steps. With the help of our efficient systems, you get fully tested, high-quality, defect-free fuel cell stacks or components in just one production step.

This combination leads to a significant increase in production capacity, while simultaneously reducing production costs.

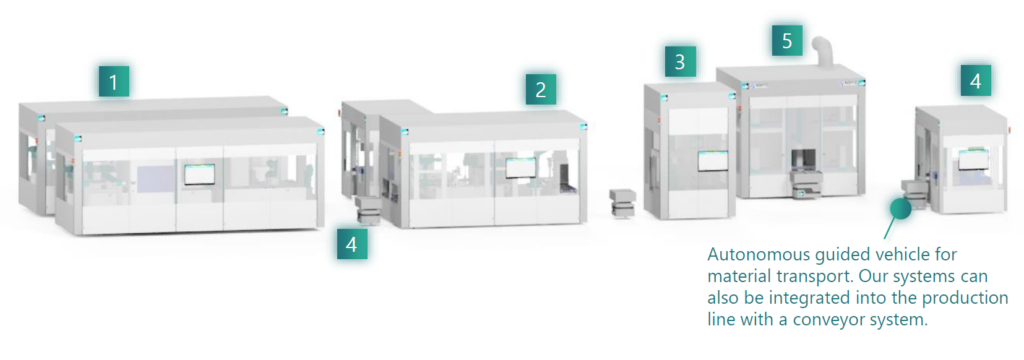

Next, we will show you some examples of plant layouts of our smart developments.

Activation and testing

This layout example shows a plant concept for the automatic loading of fuel with simultaneous activation of the electrochemical operation of fuel cell stacks or even complete fuel cell systems.

In the first step, the most important performance parameters are determined based on the characterization of the fuel cell. Subsequently, stacks and systems are comprehensively and precisely tested using our successful UTP Suite testing software. At the end of a full run, you take out a finished, safely tested and thus flawless product.

End-of-line test

This test solution is an example of automated test procedures and load simulation. It is based on the UTP 9080 modular platform from NOFFZ.

The main application of the system is end-of-line testing of fuel cell stacks with management systems. The system is controlled via our effective NOFFZ testing software UTP Suite.

The test specimens are automatically moved into the measuring cell via an individually configurable product carrier concept. Direct communication with the FCCU takes place in the measuring cell, followed by measurements and logging of all required electrical quantities.

Tracking and testing

Our bundled know-how – your advantages

Quality assurance of the stack assembly process is of enormous importance. To meet the stringent requirements, our system uses a range of test procedures to detect anomalies and verify functionality.

By collecting, processing, and visualizing test data, it enables seamless traceability – starting with material receipt and ending with the finished stack.

Flexible and scalable

Our entire portfolio of assembly and test solutions is scalable at any time. It can be adapted and expanded flexibly to different types and sizes of fuel cell products. Our systems can be integrated into existing lines or operated independently.

In other words, we adapt our system solutions to your production and your specific circumstances. Efficient – Economical – Reliable